Deutsche Bahn Launches Revolutionary New Construction Schedule Concept

Efficient Construction Management

Starting mid-July, Deutsche Bahn (DB) will implement a groundbreaking construction concept featuring fixed time windows in the schedule for maintenance and modernization projects. The "Construction on Schedule" principle aims to halve mid-year timetable changes by 2026 and bundle multiple projects into single timeframes, leading to extended periods without construction. This new approach will significantly reduce the impact of construction on passengers and freight customers. Construction partners, contracting entities, and railway companies can now plan more reliably, allowing DB and construction firms to utilize resources more efficiently.

Improved Operations and Efficiency

Dr. Philipp Nagl, CEO of DB InfraGO AG, emphasized the need for change, stating, "The current operational situation cannot continue. To improve punctuality, we are undertaking more construction than ever before. By aligning construction schedules with train timetables, we will become more organized, efficient, and capable of completing more work in the same timeframe. This means fewer disruptions for customers and more reliable schedules. This is the core idea behind 'Construction on Schedule' and reflects our commitment to public welfare."

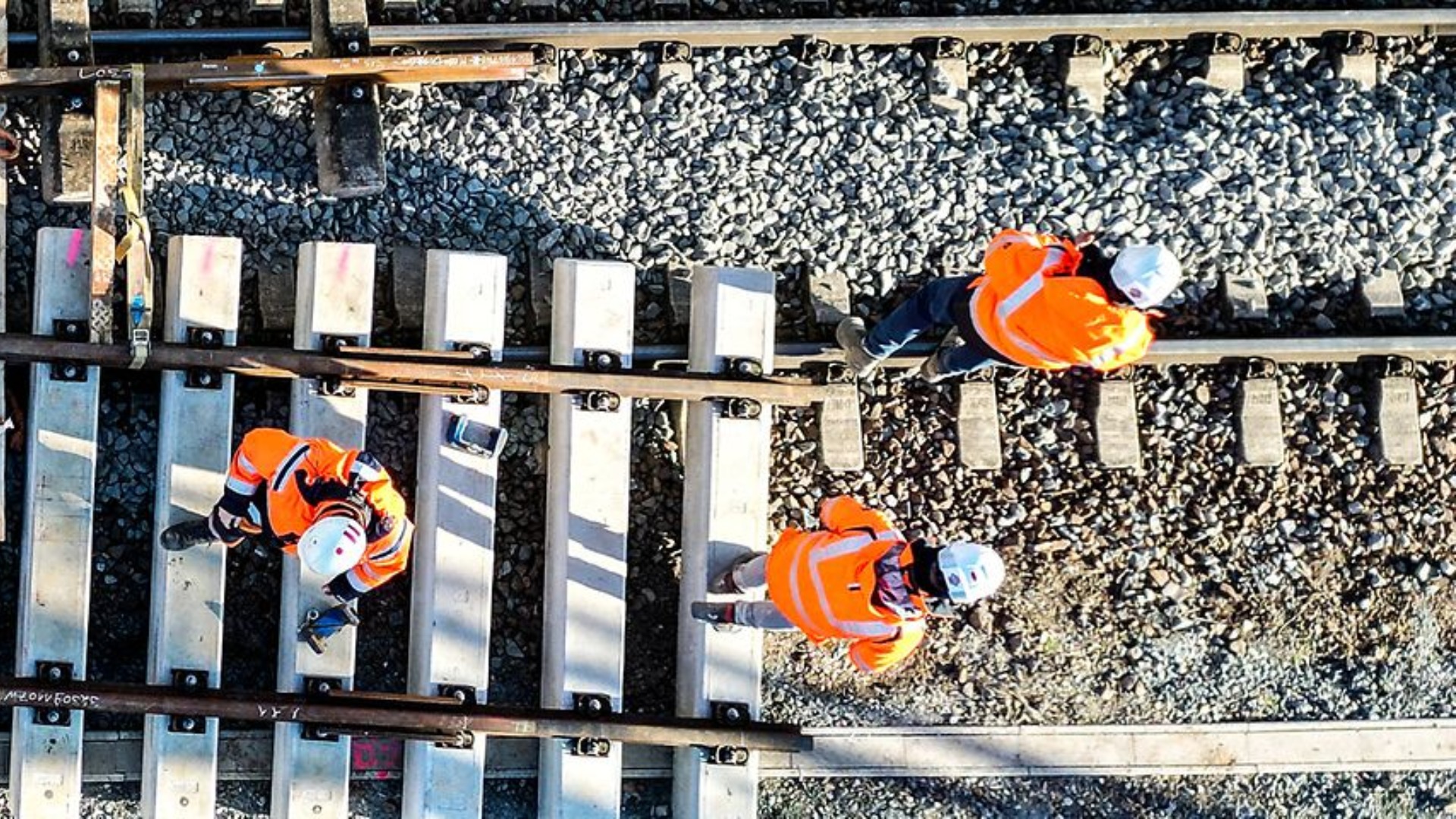

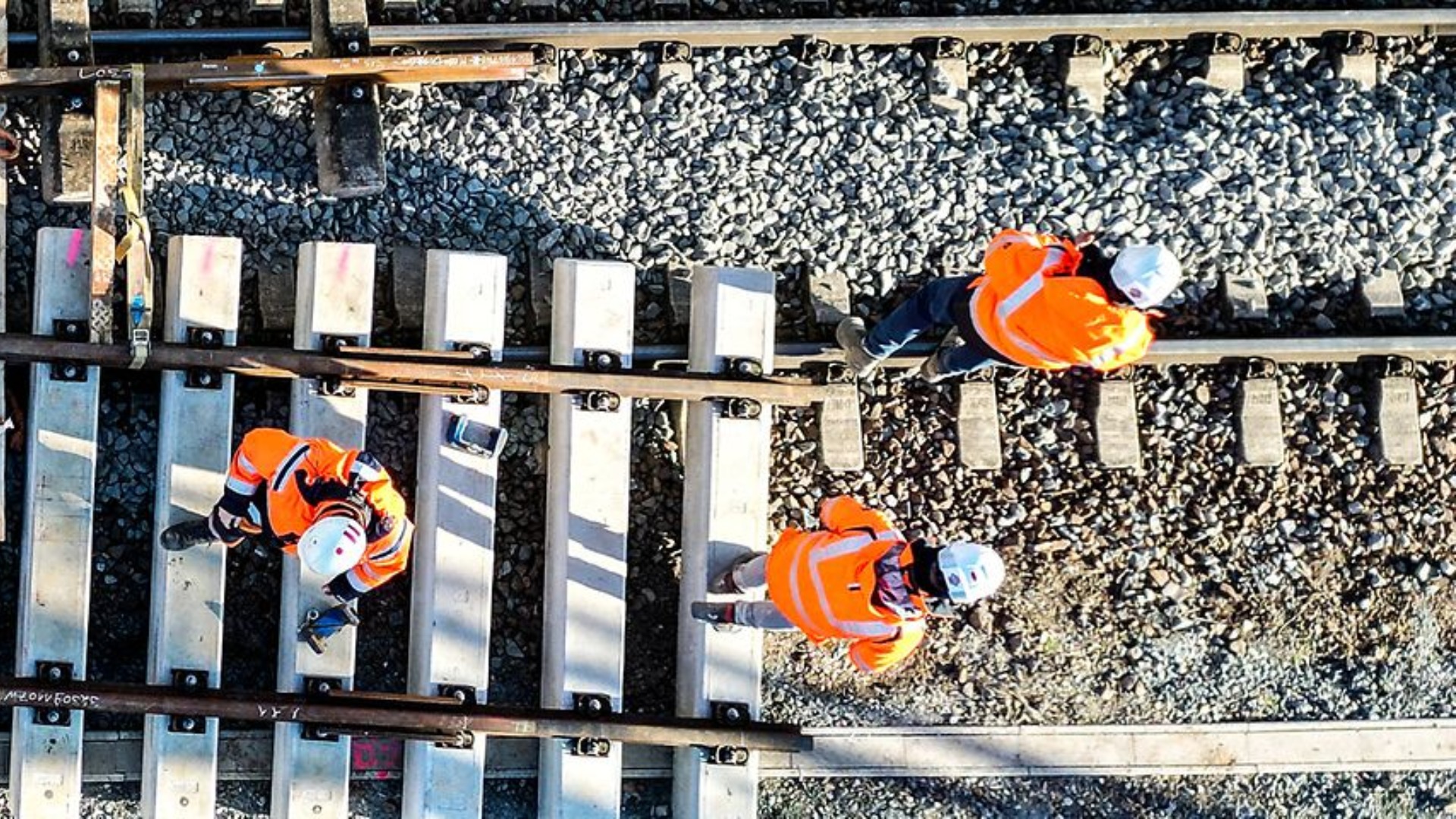

Systematic Maintenance

From mid-July, maintenance management will undergo a transformation. Maintenance teams will work on defined sections, conducting inspections and repairs mile by mile. This systematic approach aims to reduce short-term construction needs, decrease system disruptions, and stabilize operations.

Strategic and Sustainable Planning

The standardized planning process is a key element of DB’s "Strong Rail" strategy, contributing to increased rail traffic on environmentally friendly trains. Regular maintenance work will be scheduled during off-peak times, ensuring that after extensive construction projects, the tracks will be clear for uninterrupted travel.

Future Expansion Projects

The new construction management system will also apply to larger expansion and modernization projects in the coming years. Extended time windows for comprehensive construction work will be established, avoiding simultaneous projects on the same corridor or key diversion routes.

Efficient Resource Utilization

With predefined time windows, staff deployment and machine use will be stable and reliable. Construction machinery will operate in twice as many shifts, significantly enhancing efficiency compared to previous practices.

Past Challenges and Future Solutions

Previously, finding specific downtime for construction work required a cumbersome process of identifying periods when no trains were running, further straining the already limited rail network capacity amidst a growing number of construction projects. The new concept aims to streamline this process and optimize capacity use.